Case Study | Commercial | Air Conditioning

In the summer of 2018 we were employed by Fish Brothers Nissan to deliver an integrated heating and cooling air conditioning system to their new vehicle servicing and maintenance premises in Swindon. The installation incorporated the service reception area and all associated offices.

At Shield Electrical, we are invested in the local community and committed to supporting the local economy through a number of key objectives; employing local engineers, sourcing from trusted local suppliers, operating an apprentice training programme and partnering on bespoke jobs with local professional service providers and tradesmen.

As a REFCOM registered contractor, our engineers have CITB certification (J11 F-Gas CAT1) for refrigeration safe handling, and our work is backed by industry approved accreditations including CHAS, SafeContractor and TrustMark. Any accompanying electrical work and testing that is required during an installation is carried out by our team of qualified electricians, all of whom carry ECS cards.

PROJECT IMPLEMENTATION

We were contracted by Fish Brothers Nissan to commence work on the project and, in preparation, the management team at Shield prepared a comprehensive ‘Management of Works’ checklist which included:

- A detailed Construction Phase Plan.

- Risk and method statements prepared to ensure all Health and Safety preparations are made including any relevant asbestos R&D reports if applicable.

- Resource planning to ensure the required qualified workforce is made available for the project including air conditioning engineers, electricians, surveyors and an office-based support team.

- Product sourcing plan with trusted local suppliers to ensure high-spec products are supplied within budget and on time.

- Quality management process to ensure a schedule of regular onsite checks on works and materials.

- A Quality Assurance Plan (QAP) identifies the strategy and controls currently employed by Shield to consistently deliver the products and service required by the client.

- Communications plan with Fish Brothers Nissan to ensure all projects requirements are being met, every step of the way.

- Works schedule to ensure the job is completed and delivered on time.

“This project saw us deliver a full service solution including everything from design, installation and testing, to inspection and commissioning of the air conditioning system and any associated electrical works”

Dom O'Bryne, Project Manager

Once work commenced, our team of engineers adhered to the strict control measures set during the planning phase and worked closely with Fish Brothers Nissan to deliver the following:

- Assess, make safe and remove an existing R22 refrigerant in accordance with licenced disposal.

- Design and implement a replacement air conditioning system based on the new layout, with consideration to type, usage and comfort requirements for each room.

- Create a multi split system to accommodate the limited external space, thus creating the smallest footprint possible.

- Use the latest R32 refrigerant gas to future proof the installation with the knowledge that R410a gas will be phased out.

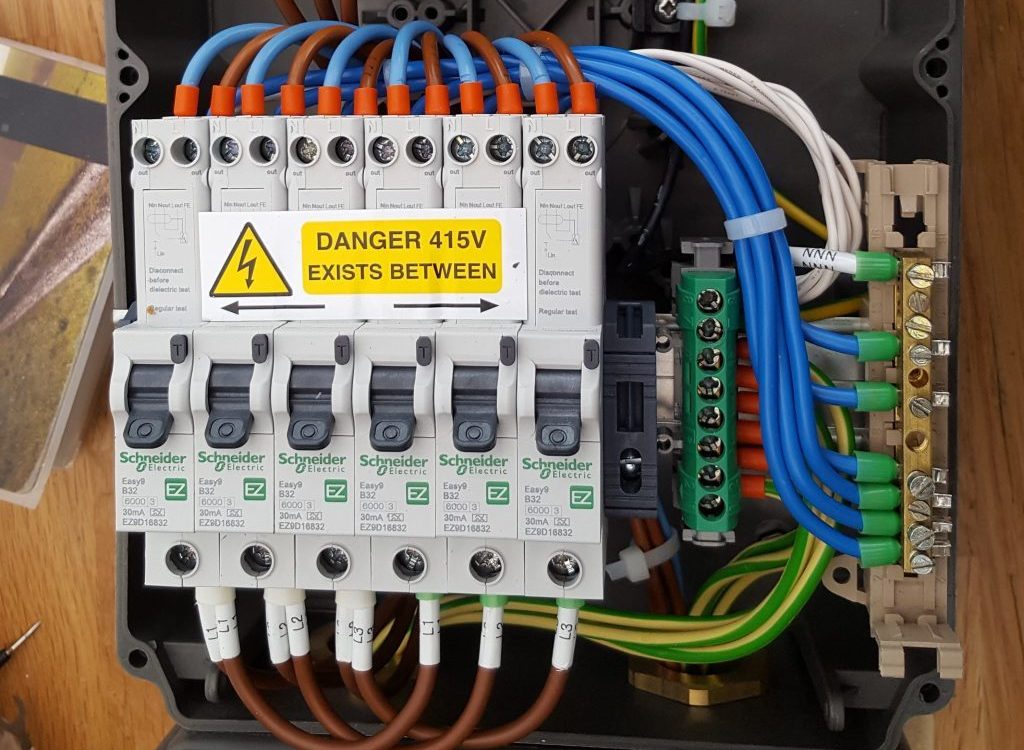

As always, our work adhered to the strict control measures set during the planning phase and our engineers completed the inspection, testing and commissioning in line with Refcom requirements. Any accompanying electrical works met the required Part P and IET Wiring Regulations. Our Quality Control Manager then completed the relevant spot checks to ensure all works met quality standards and the required client specification before issuing as fitted documentation and certificates.

SUMMARY OF WORKS

This project saw us deliver a full service solution including everything from design, installation and testing, to inspection and commissioning of the air conditioning system and any associated electrical works.

Throughout the project, our team worked closely with the building contractors which enabled us to install the refrigerant and condensate pipework into the fabric of the building, avoiding unsightly trunking and drainage pipework. This further enhanced the finish of the stylish cassette units we installed, allowing us to deliver both a fully functional and modern air conditioning system for the client.